Kiwiplan - Multi-Plant Harmonization

What fields and areas that need to be standardize in ESP and MAP.

This section was put together from the aspect if we were going forward either with one MAP database or Multi-MAP databases scenario.

All plants in one ESP database

Here is a list of fields/lookups that need to be standardized in the ESP database

-

Destination Codes

-

Styles for Descriptions and print outs

-

Stacking Patterns shared with MAP parameters

All countries/states/provinces in a separate MAP Database

Here is a list of fields/lookups that need to be standardized all across the MAP databases

-

Colors

-

Pallet Types

-

Top Board Codes

-

Closure Codes

-

Strapping Codes

-

Stacking Patterns shared with ESP

-

Tab Types

-

Score Types

-

Ink Types

10) Tools Types

11) Tool Names when the tool is shared

12) Machine Operations

13) Unit Descriptions

14) Basic Board Codes

15) Downtime Codes

16) Waste Codes

17) Machine numbers

18) BRD-ST, Material Status

19) CORR-FL, Corrugator flutes

20) CSC-BS, Board structure

21) CSC-CC, Coating codes

22) CSC-OS, Order status codes and desc

23) CSC-PC, Paper class

24) GEN-FB, Default waste codes

25) GEN-LT, Label types

26) GEN-QC, Down time categories

27) GEN-UM, Units of measure

28) GEN-WC, Waste code classes

29) PCS-QE, PCS - machine groups

30) PCS-QO, PCS - order status

31) PCS-QR, PCS - run rate units

32) Label Formats

33) Board Code

Board Codes

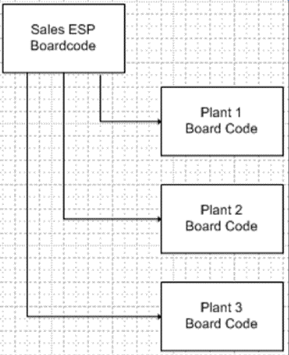

The image below shows how we would setup board codes to be used in MAP. The ESP sales board code would only be seen in ESP for costing and sale purposes. The plant board code would only be seen on the production side and used to produce the item. Depending on the local plant’s available papers the combination would change at every plant. The producing plant’s combination would be setup in the CSC system to have an upgrade downgrade path to the top board code from sale board code.

NOTE: There is currently a limit to 16 upgrade and downgrade paths.