Kiwiplan - Supplying Product Designs

This section describes how to set up one product design to be supplied by another. This scenario is needed when goods are produced for stock, but must be erected/finished at a future unknown date. This means we need a means of tracking stock of the unfinished product and finished product.

ESP and MAP provide a solution for this using two stock PD’s. The first one (unfinished) is converted and booked into store. When the last conversion process is required, a topup of the second (finished) PD is placed. The feedback of this topup order will automatically decrease the stock of the first PD.

Parameters, Store and Machine Setup

Machine Setup

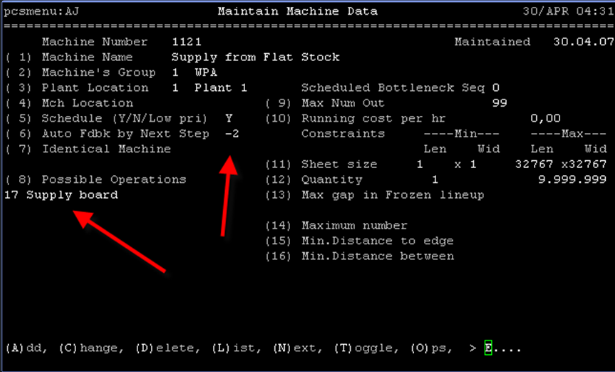

For this to work there are two machines that must be set up correctly. There must be a Supply From Stock machine. This machine should have the Supply operation 17, and be set to auto-feedback, triggered by feedback of the next step.

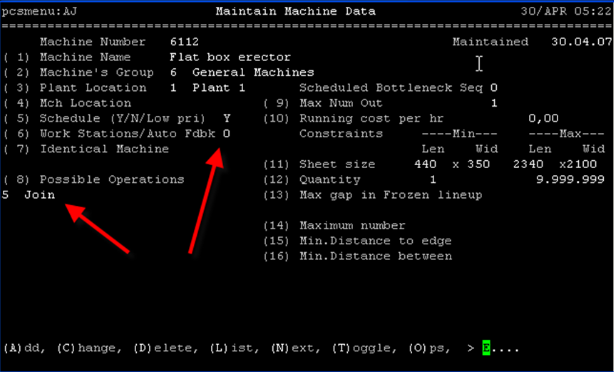

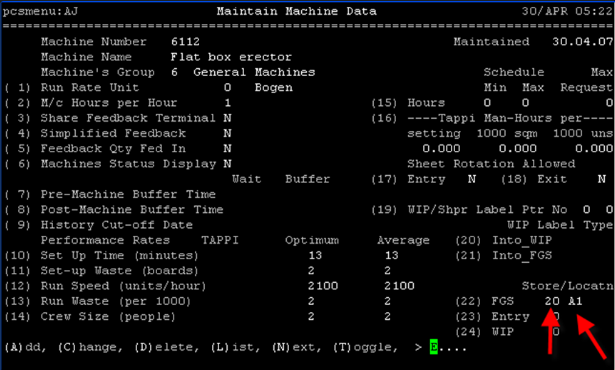

The second machine is the conversion machine that finishes the product. This machine should have standard feedback, the operations that are required to finish the product, and be attached to the store and location where the unfinished product will be stored.

Store Setup

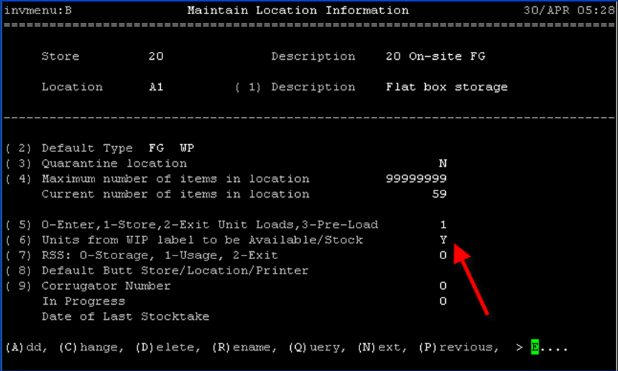

The store location where the unfinished product is stored must have ‘Units from WIP label to be Available/Stock’ set to Y.

Parameters

Two parameters need to be set in MAP:

-

PCS FB 57 “Auto Board Xfers for Hort Jobs” = Y

-

GEN PL 33 “FGS Supply Machine for Hort.” = machine number for Supply From Stock machine

Product Design Setup

Unfinished Product Design

This PD must have a stock line for the store that was specified on the finishing machine described previously in this section.

The machine route should be set up as normal, without the finishing step.

Finished Product Design

The finished PD must also have a stock line.

The machine route should be the Supply from Stock machine, the finishing machine and the strapper, so the operations on the PD need to be Supply board, whatever finishing operations are required, and strapping.

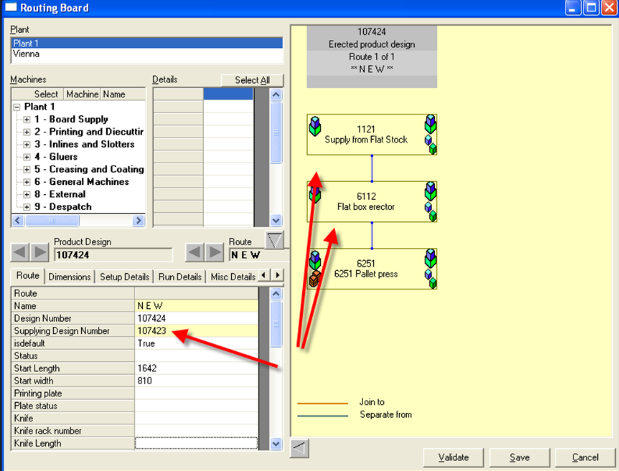

The machine route should have the unfinished PD number specified in the ‘supplying design number’ field.

Business Rule for Special Instruction

There is currently nothing on the order for the finished PD to indicate that it is being supplied by another PD. However this can be easily remedied by writing a business rule to the Order business class that adds the supplying PD number to the special instructions.

Expression:

[Specialinstructions]:=[Specialinstructions] & iif([Ordertype]<>"calloff" AND isobjectvalid([Route.SupplyingProductDesign])=true AND findcount("to supply this order",[specialinstructions])=0," !!!!! Please use PD" & [Route.SupplyingProductDesign.Designnumber] & " to supply this order !!!!!","")

This rule appends a message to the existing special instructions, but only if the following conditions are true:

-

the order is not a calloff

-

the route attached to the order has a supplying PD number

-

the message isn’t already in the special instructions

The message that is added to the special instructions:

!!!!! Please use PD**** to supply this order !!!!!

where **** is the supplying PD number from the machine route.

Ordering, Feedback and Delivery

Here is the sequence of events for this scenario:

-

topup is placed for the unfinished PD to increase the stock. It is converted and booked into store

-

topup is placed for the finished PD

-

the finishing step is fed back

-

this automatically feeds back the Supply from Stock step, drops the unfinished stock levels and increases the finished stock levels

-

calloff order is placed for delivery of finished product